What is an intermittent fault measurement?

An intermittent fault only presents itself from time to time, e.g as result of temperature fluctuations or mechanical loads. Measuring an intermittent fault can therefore be a long search for defective components or damaged wiring and connectors that have a bad connection.

To measure intermittent faults the TiePie oscilloscopes can be set up to measure continuously before the faults occur. The moment the fault occurs the space bar or manual trigger button can be pressed to trigger the measurement and finish it. An intermittent fault measurement makes it possible to measure signals both before and after the fault occurs.

How do I perform an intermittent fault measurement?

The following settings for an intermittent fault measurement can be used with every TiePie oscilloscope and lab scope like the Automotive Test Scope ATS5004D:

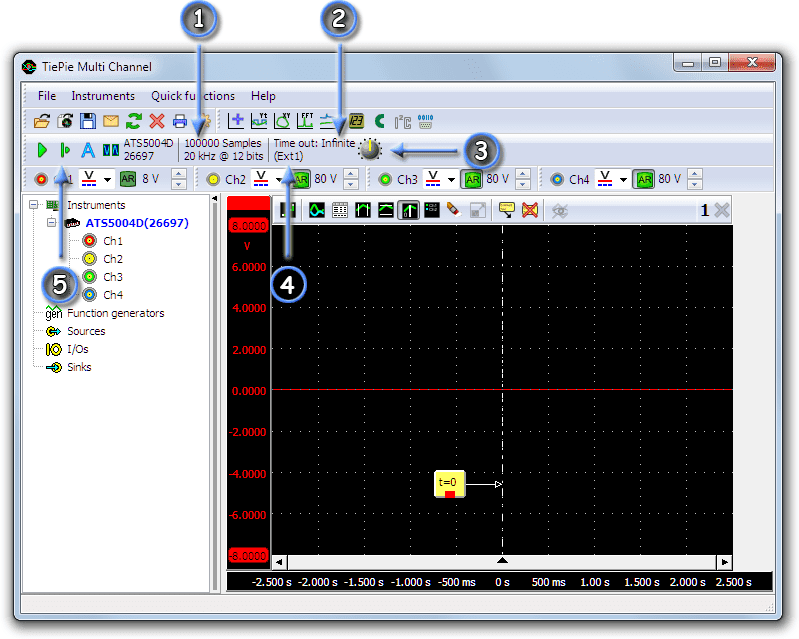

- Make sure the measuring time is at least several seconds long. Therefore set the sample frequency at a sufficiently high level and the record length at several times the sample frequency. Select e.g. 20 kS/s and 100 kS. The measuring time becomes 100/20 = 5 seconds.

- Set the trigger time out to infinite so the measurement is only performed when a trigger is given.

- Set the pre trigger for sufficient measuring time before and after the trigger. Select e.g. 50% to measure equally long before and after the trigger.

- Set the trigger source to external so the manual trigger button can be used.

-

Perform a one shot measurement by pressing the

One shot button or the hotkey O.

One shot button or the hotkey O.

When the fault occurs, e.g. a hesitating engine, the measurement must be triggered (with above mentioned settings) within 2.5 seconds by pressing the space bar or the external manual trigger button. After triggering the measurement is being finished, sent to the Multi Channel oscilloscope software and the measured signals become visible. When triggering was in time, the signals before t=0 (trigger moment) should contain the fault. The signals after the trigger moment are also interesting, because they can contain the results of the fault.

It is possible to use all channels of the TiePie oscilloscope for an intermittent fault measurement, by selecting the desired range of the channel and drag it into the graph.

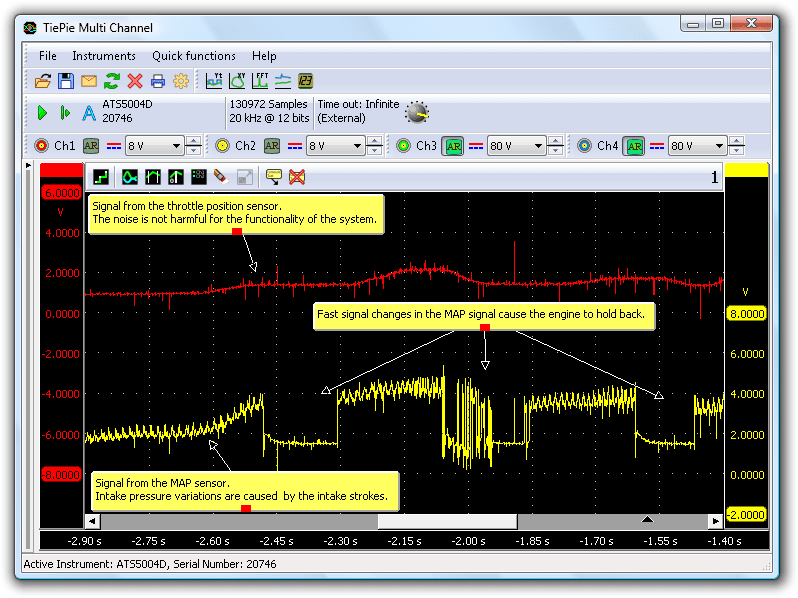

Figure 2 shows an example of a measurement where the intermittent fault measure mode is used to measure an engine fault. Read the whole article: Peugeot 205 holding back.

RELATED PRODUCTS

RELATED INFORMATION

- Honda Jazz holds back and stalls

- A 2006 Honda Jazz with L13A i-DSI engine occasionally holds back and sometimes even stops. No error codes were stored in the car. Several components have been replaced or swapped with an other car. A lot was driven in the car with a scanner hooked up to monitor the "live data" to find an anomaly in sensor or actuator data. Nothing showed up. Only after diagnosing with a good automotive diagnostic oscilloscope, the cause of the problems was revealed.

- Peugeot 205 holding back

- When a Peugeot 205 is performing a strong accelleration, it starts holding back. When it is cruising, nothing is wrong. Several components were replaced, without result. The automotive oscilloscope was used to measure various signals, which led to finding a simple mechanical problem.

- Saab 9-5 with intermittent hiccups

- The engine of a 1999 Saab 9-5 intermittently shows a "hiccup" but then continues to run properly. Over time, the problem became worse and and at some point, the car would not start for 20 minutes. The owner consulted a garage that concluded that the special Direct Ignition cassette needed replacement. Unfortunately that did not solve the problem. Time to start measuring properly, using an automotive diagnostic oscilloscope.