Sensor information

| Type: | NTC temperature sensor |

|---|---|

| Power supply: | Ground |

| Signal type: | Amplitude varying |

| Signal level: | 0.2 V hot to 4.0 V cold |

Workings of the coolant temperature sensor

The coolant temperature sensor has a built-in NTC resistor. The resistance of a Negative Temperature Coefficient (NTC) resistor decreases when the temperature increases. The resistor in the sensor together with a resistor in the ECU forms a voltage divider which is fed by a 5 V power supply. If the temperature changes, the resistance and the signal voltage at the dividers output changes. The ECU is able to determine the engine temperature from the sensor signal voltage and adjusts the injector opening time. In this measurement example the signal voltage of the coolant temperature sensor is measured.

Connecting the lab scope

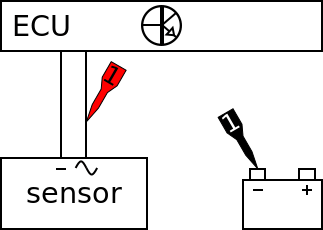

Correct functioning of the coolant temperature sensor can be checked by measuring the following signal voltages, see figure 1:

| Channel | Probe | Voltage | Range |

|---|---|---|---|

| 1 |  |

Sensor output signal | 4 V |

|

Ground at battery |

The lab scope is connected to the coolant temperature sensor via a Measure lead TP-C1812B and Back Probe TP-BP85 and set to recorder mode. In recorder mode a streaming measurement is performed, continuously displaying the signals live on screen. Because the measured signals vary slowly, the Automotive Test Scope ATS5004D is set to a slow measuring speed.

Measuring

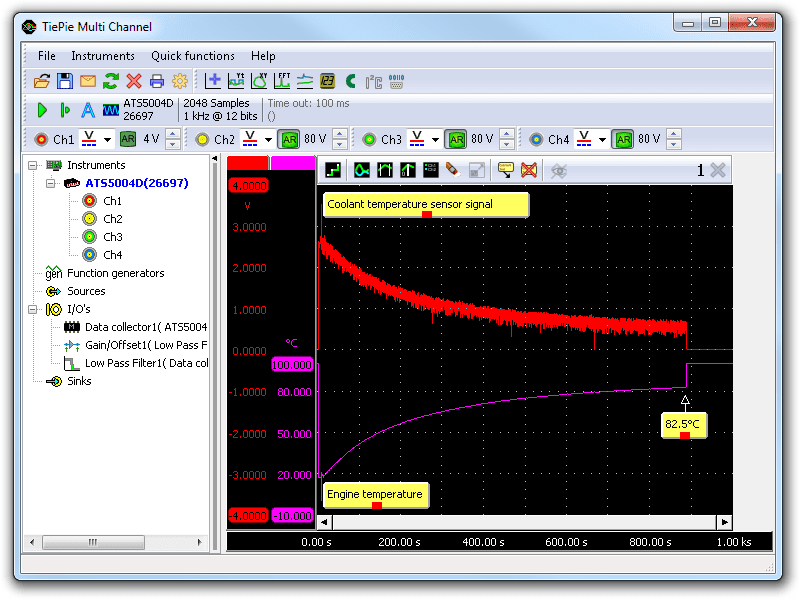

Figure 3 shows a waveform of a coolant temperature sensor during the engine warming up. This signal can be downloaded and used to correctly set up the lab scope or as reference signal.

Download coolant temperature sensor measurement

Channel 1 (red) shows the signal of the coolant temperature sensor during a warming up of the engine. At the beginning of the measurement the key is switched on and shortly after the engine is started which can be seen from the spike in the signal voltage. After the engine has fired up, the voltage starts to decrease due to the warming of the engine. This measurement is made with an outside temperature of 17°C which corresponds with a signal voltage of 2.5 V. The measurement is taken until the engine has reached a temperature of 82.5°C. The sensor signal has been converted to the actual engine temperature with a Gain/Offset I/O. The purple line shows resulting engine temperature. The settings of the Gain/Offset I/O in this measurement example are specific for the type of temperature sensor used in the particular car that is measured.

Diagnosis

Signal values may differ on different types of engine control units and coolant temperature sensors. Consult ATIS for information on specific engine control units and temperature sensors.

The following signal deviations can indicate a problem:

-

No signal:

Cause: back probes have no connection (perform a connection test), shorting to ground, sensor defective -

Signal voltage too high:

Cause: poor or no ground , sensor defective -

Noisy signal:

Cause: wiring of signal or ground wire damaged, poor connection in connector terminals, sensor defective -

Signal shows an offset:

Cause: scope is not set to DC coupling: ,

poor ground, sensor defective

,

poor ground, sensor defective

RELATED PRODUCTS

RELATED ARTICLES

- Indirect injection voltage measurement

- A lab scope is used to measure an injector signal voltage on an idling engine at operating temperature. The signal from the sensor is shown and can be downloaded. To help determining whether the injector is functioning correctly, different possible deviations from the example signal are mentioned along with possible causes.

- Audi A8 will not start

- An Audi A8 refuses to start right after it has been driven. Only after letting it cool down, it will start again. The dealer was unable to fix this. After measuring various signals with an automotive oscilloscope, the problem could be traced back to a malfunctioning coolant temperature sensor.

This document is subject to changes without notification. All rights reserved.

The information in this application note is carefully checked and is considered to be reliable, however TiePie engineering assumes no responsibility for any inaccuracies.

Safety warning:

- Before measuring, check that sources of dangerously high voltages are switched off or shielded from contact. Voltages considered to be dangerous are voltages over 30 V AC RMS, 42 V AC peak or 60 V DC.

- Keep a clean working environment when doing measurements.

- This measurement and procedures are a examples / measuring suggestions and are no prescribed protocols.

- TiePie engineering can not anticipate the safety actions that need to be taken to protect persons and appliances. Before starting a measurement, check which safety measures need to be applied.